Polypropylene Meltblown Filter Cartridge

Products

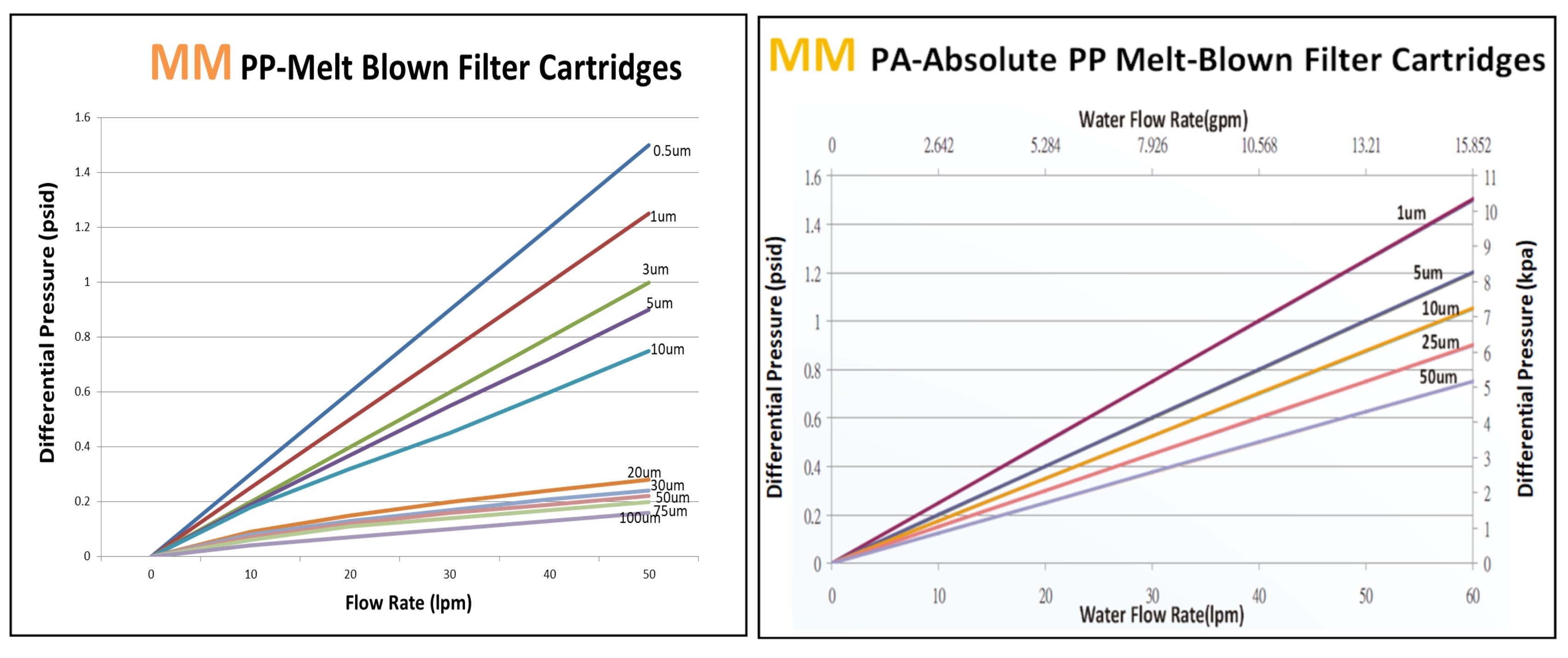

The PP (Polypropylene) material is formed by hot melt extrusion, where high temperatures fuse the fibers together. The density of the filter material is controlled by varying the forming speed and the distance of fiber collection. The standard filter cartridge features a double-layer structure, directly formed by hot melt and high pressure. Due to the uniform pore density of the formed cartridge, it has a strong structural integrity, vibration resistance, and excellent chemical resistance from the PP material, making it a high-quality filtration medium. The filter cartridge has an outer coarse and inner fine structure, which allows it to evenly trap contaminants of varying densities within the inner and outer layers of the cartridge, reducing resistance, increasing liquid flow rate, and providing excellent depth filtration and contaminant removal. This ensures stable flow and pressure differentials, making it suitable for a wide range of applications. PP filter cartridges are economical, efficient, and stable filtering materials. 10"、20"、30"、40"

Polypropylene Meltblown Filter Cartridge

Polypropylene ,PPProduct Advantages